Transforming Stainless Steel Fabrication – Deep Dive into Handheld Laser Welding Applications

Analysis of the application value of hand-held laser welding machine in stainless steel processing

Stainless steel is the backbone material of industries like kitchenware, elevators, medical devices, and architectural elements due to its corrosion resistance, strength, and aesthetics. However, traditional welding methods such as TIG or arc welding often fall short in delivering seamless results — with issues like warping, rough seams, and slow productivity.

East Laser’s handheld fiber laser welding machine brings a revolutionary solution to stainless steel fabrication, blending precision, flexibility, and cost-efficiency into one compact system.

🔧 Key Technical Advantages:

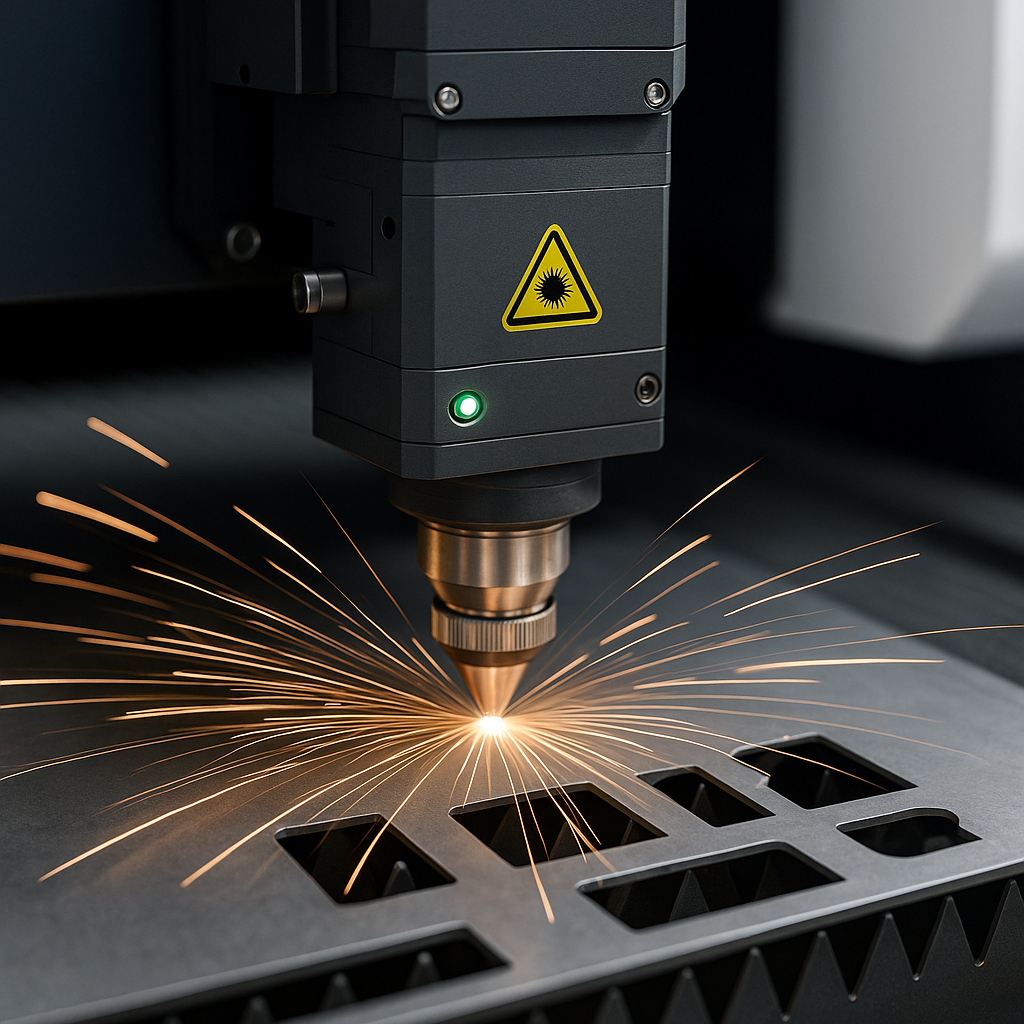

🔹 Ultra-precise welding with minimal distortion

Laser beams concentrate high energy into a tiny spot, producing slim and smooth weld seams with minimal heat-affected zones — ideal for thin stainless steel plates and decorative finishes.

🔹 3–5× faster than traditional methods

Our continuous fiber laser achieves welding speeds of up to 2 meters/minute, drastically increasing throughput — great for volume manufacturing.

🔹 Superior flexibility for complex shapes

Handheld operation suits tight corners, curved edges, cylinders, and custom-designed components — far beyond the reach of rigid fixtures.

🔹 Lower long-term production costs

With reduced labor needs, minimal polishing, and low power consumption, laser welding saves money over time despite a higher initial investment.

🔹 Eco-friendly & automation-ready

Built-in safety systems, smoke filtration compatibility, and integration potential with robotic arms or automation lines make it future-ready.

✅ Real Applications in Stainless Steel:

Kitchenware: Sink, cabinet, and oven body welding — requires perfect appearance and tight seals.

Elevator Fabrication: Large stainless panels and handrails benefit from deformation-free welding.

Doors & Fences: Fine welds boost aesthetic value for luxury stainless steel frames.

Medical Devices: High hygiene and strength requirements met with clean laser welds.

Water Tanks & Tubing: High penetration welding ensures leak-proof durability.

💬 Client Feedback:

"We replaced traditional TIG with East Laser’s handheld laser welder — the improvement is stunning! Clean welds, faster delivery, and easier training for workers."

"No need for grinding anymore. It’s now our main tool for stainless products."

Contact Information:

📞 WhatsApp: +8618958697435

📩 Email: eastlaserok@gmail.com

🌍 Official Website: www.east-laser.com