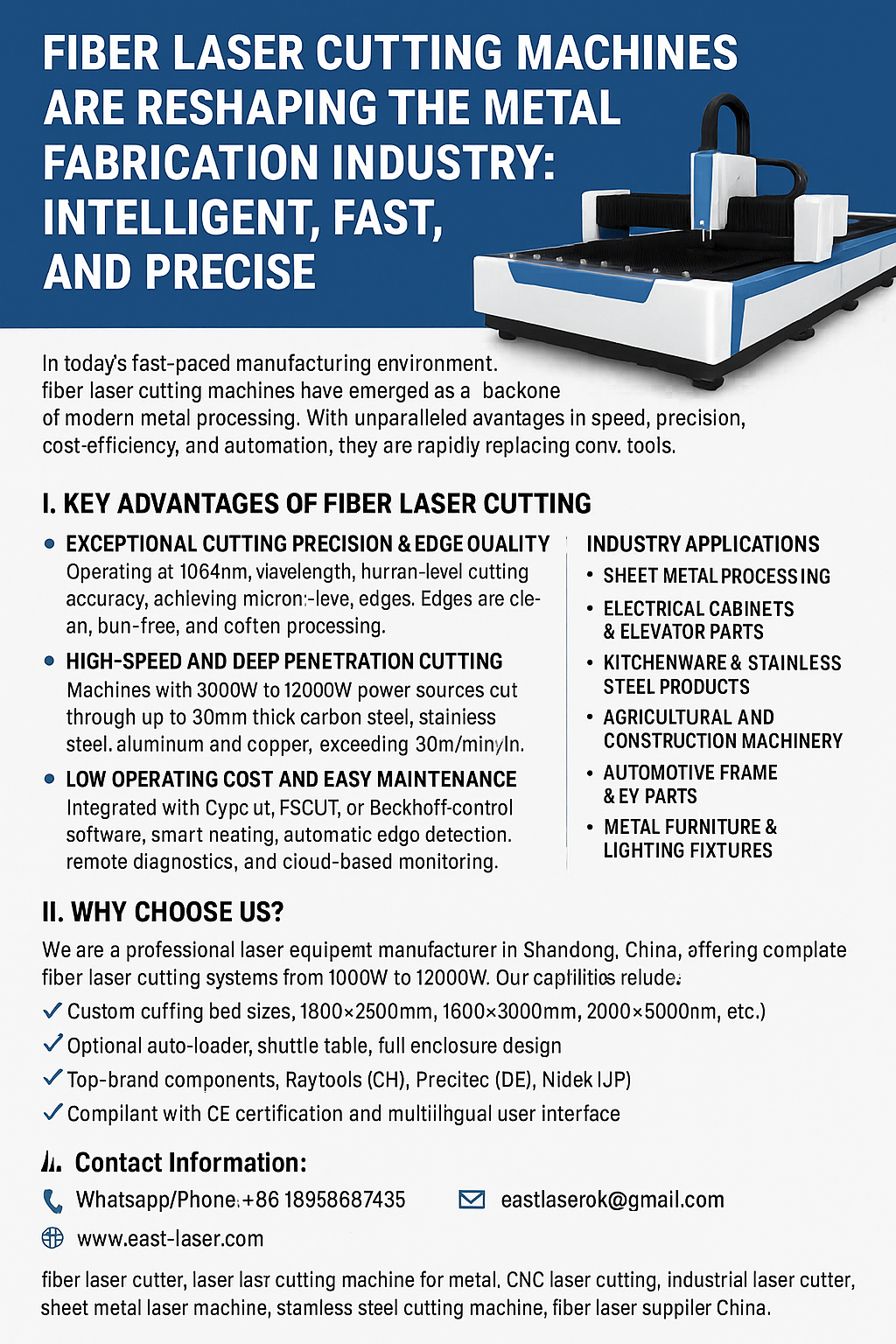

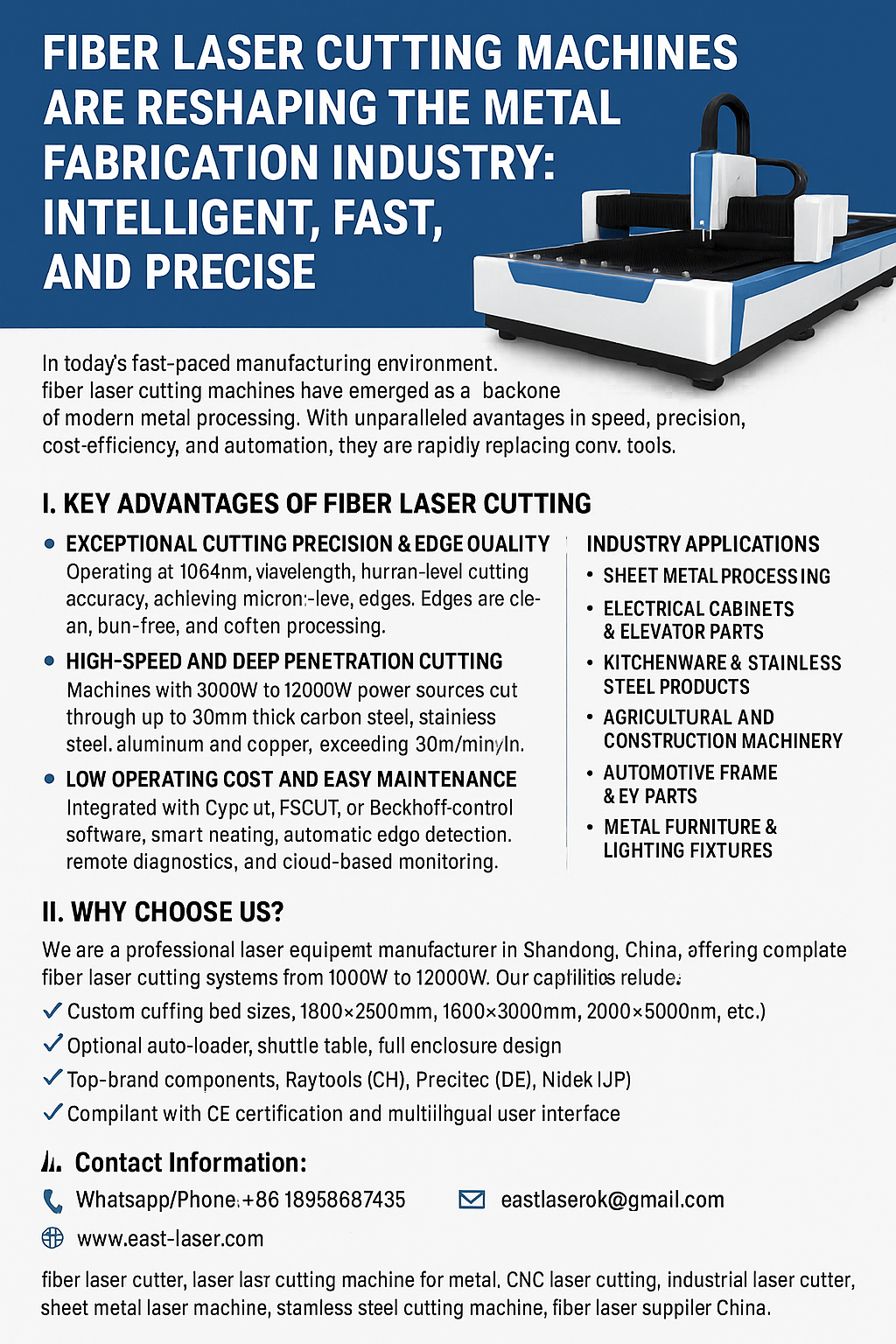

Fiber Laser Cutting Machines Are Reshaping the Metal Fabrication Industry: Intelligent, Fast, and Precise

Intelligent, Fast, and Precise

In today’s fast-paced manufacturing environment, fiber laser cutting machines have emerged as the backbone of modern metal processing. With unparalleled advantages in speed, precision, cost-efficiency, and automation, they are rapidly replacing conventional cutting tools like plasma, flame, and waterjets.

I. Key Advantages of Fiber Laser Cutting

Exceptional Cutting Precision & Edge Quality

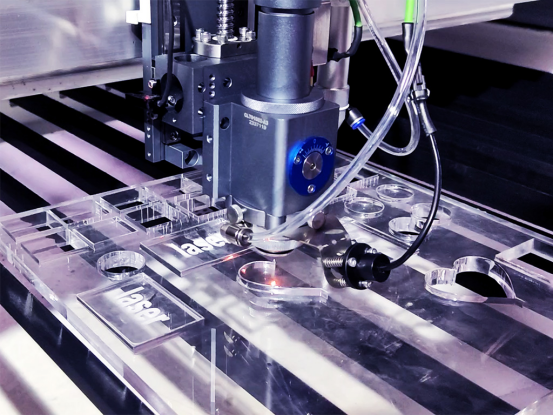

Operating at a wavelength of 1064nm, fiber lasers deliver ultra-fine beam quality, achieving micron-level cutting accuracy. Edges are clean, burr-free, and often require no secondary processing.

High-Speed and Deep Penetration Cutting

Machines equipped with 3000W to 12000W power sources can cut through up to 30mm thick carbon steel, stainless steel, aluminum, and copper with cutting speeds exceeding 30m/min.

Low Operating Cost and Easy Maintenance

Unlike CO₂ lasers, fiber lasers use no mirror alignment, reducing energy consumption and maintenance time. Their modular design ensures quick part replacement and serviceability.

Smart CNC Control Systems

Integrated with CypCut, FSCUT, or Beckhoff control software, our machines offer smart nesting, automatic edge detection, remote diagnostics, and cloud-based monitoring—ideal for Industry 4.0 workflows.

II. Industry Applications

Sheet Metal Processing

Electrical Cabinets & Elevator Parts

Kitchenware & Stainless Steel Products

Agricultural and Construction Machinery

Automotive Frame & EV Parts

Metal Furniture & Lighting Fixtures

From bulk production to on-demand customization, fiber laser cutters offer unmatched productivity and adaptability.

III. Why Choose Us?

We are a professional laser equipment manufacturer in Shandong, China, offering complete fiber laser cutting systems from 1000W to 12000W. Our capabilities include:

❇️ Custom cutting bed sizes (1300×2500mm, 1500×3000mm, 2000×6000mm, etc.)

❇️ Optional auto-loader, shuttle table, full enclosure design

❇️ Top-brand components: Raytools (CH), Precitec (DE), Nidek (JP)

❇️ Compliant with CE certification and multilingual user interface

Contact Information:

📞 WhatsApp: +8618958697435

📩 Email: eastlaserok@gmail.com

🌍 Official Website: www.east-laser.com

Share This Article With Others

Further Reading

Jul 25, 2025

1 Min Read

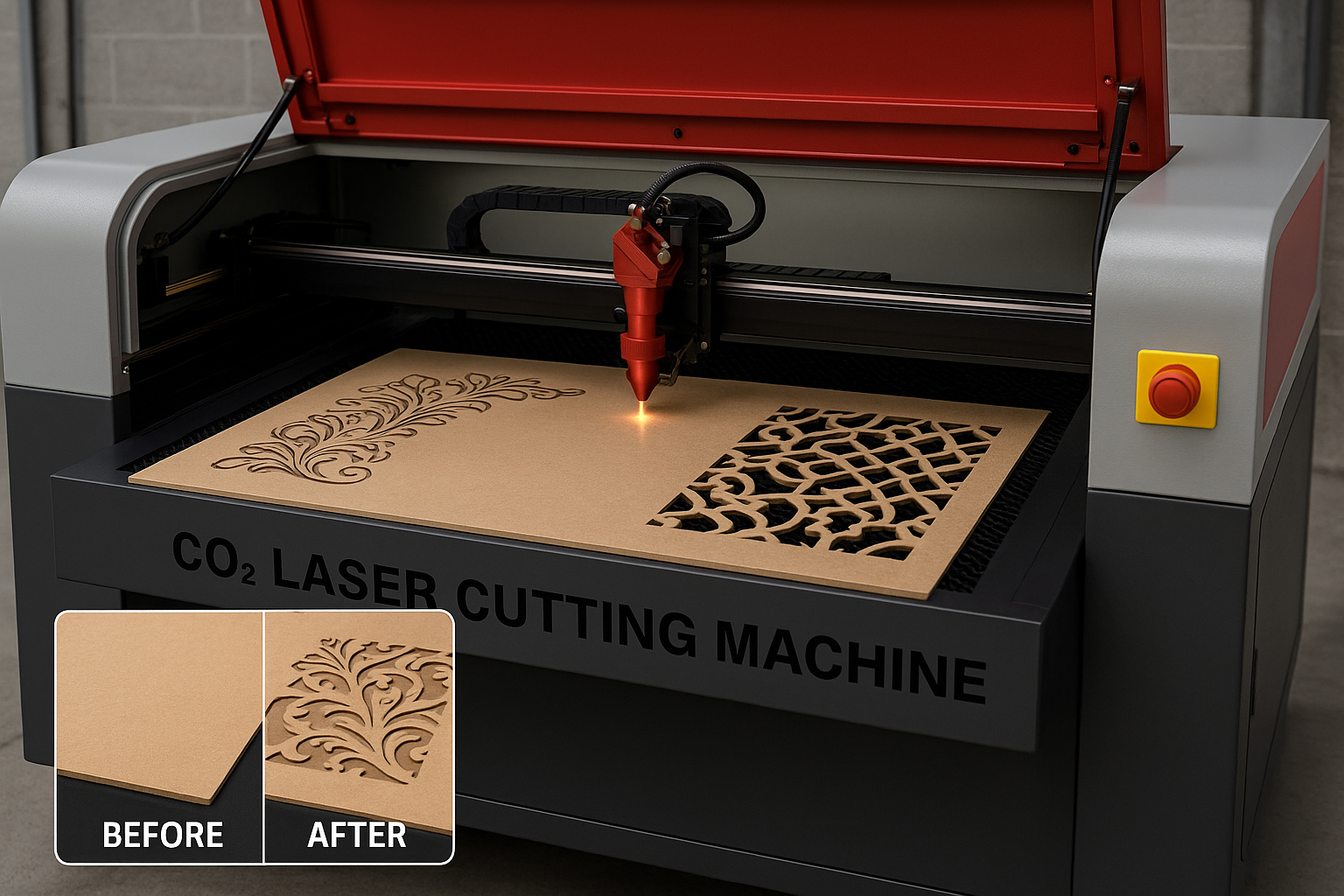

In today’s advertising and packaging industries, precision, customization, and efficiency are essential. Traditional cutting methods often struggle with misalignment, high material waste, and heavy operator reliance—problems that are now solved with our Vision-Positioning CO₂ Laser Cutting Machine.

Dec 19, 2024

1 Min Read

plasma cutters are versatile tools that can be used in a variety of industries to cut metal quickly and accurately. the cost of a plasma cutter can vary greatly depending on a variety of factors including brand, quality, power output, additional features, and intended use.

Jul 23, 2025

1 Min Read

laser cutting acrylic is one of the latest developments in our technology, making the manufacturing process of acrylic sheets more efficient and providing unparalleled precision when engraving, engraving or shaping. this high-performance technology opens up a world of creative possibilities.

Dec 19, 2024

1 Min Read

laser rust removal is a modern laser cleaning machine that effectively removes rust and corrosion from metal surfaces using a high-intensity laser beam. it provides a very accurate and environmentally friendly solution compared to other methods. the price of a rust removal laser depends on its functionality and power, ranging from approximately $10,000 for entry-level systems to over $100,000 for high-power systems.

Jul 23, 2025

1 Min Read

As industrial automation and intelligent manufacturing continue to advance, laser processing technology has become increasingly mature. In the field of non-metal materials, the CO₂ laser cutting machine stands out as an essential and advanced tool thanks to its high efficiency, stability, and excellent cutting quality. This article provides a comprehensive analysis of CO₂ laser cutting machines from four perspectives: working principle, application fields, technical advantages, and market prospe

Jul 26, 2025

1 Min Read

Stainless steel is the backbone material of industries like kitchenware, elevators, medical devices, and architectural elements due to its corrosion resistance, strength, and aesthetics. However, traditional welding methods such as TIG or arc welding often fall short in delivering seamless results — with issues like warping, rough seams, and slow productivity.East Laser’s handheld fiber laser welding machine brings a revolutionary solution to stainless steel fabrication, blending precision, flex