Break the Limits! Vision-Positioning CO₂ Laser Cutting Machines Lead the Future of Smart Manufacturing in Advertising & Packaging

Vision-Positioning CO₂ Laser Cutting Machines Lead the Future of Smart Manufacturing in Advertising & Packaging

In today’s advertising and packaging industries, precision, customization, and efficiency are essential. Traditional cutting methods often struggle with misalignment, high material waste, and heavy operator reliance—problems that are now solved with our Vision-Positioning CO₂ Laser Cutting Machine.

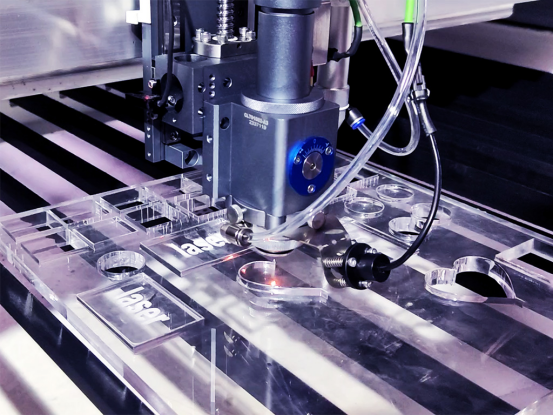

Integrated with an industrial-grade CCD camera and intelligent image recognition software, this machine can automatically detect positioning marks or graphic edges and generate precise cutting paths—without manual intervention. From acrylic lightboxes and PVC panels to printed paperboard, vinyl, or PET, the machine handles irregular materials with speed and accuracy.

🎯Customer Pain Points:

Manual alignment is time-consuming and error-prone?

Complex graphics take too long to set up?

High-volume orders bottleneck your productivity?

Cutting quality lacks consistency?

✅Our Solution: Vision Laser Cutting with Intelligent Auto-Recognition

⭐Key Advantages:

Automated Visual Recognition – no operator needed for alignment

Wide Software Compatibility – works with CorelDRAW, AI, CAD, PDF, and more

Smart Auto Compensation – corrects positional errors during operation

Batch Processing Ready – detect and cut multiple pieces in one go

Smooth Edges, No Burrs – perfect for high-end signage and craft applications

📐Recommended Models:

EAST-VS9060 Vision CO₂ Laser Cutter (medium format)

EAST-VS1390 Smart Visual Laser System (large format)

EAST-VS1610 Dual-head CCD Vision Laser Cutter (for sync-cutting)

📦Typical Applications:

Acrylic signboards, lightbox letter cutting

Display boards, architectural models, and signage

Die-cutting printed paper boxes

Personalized crafts & commercial printing finishing

Contact Information:

📞 WhatsApp: +8618958697435

📩 Email: eastlaserok@gmail.com

🌍 Official Website: www.east-laser.com

Share This Article With Others

Further Reading

Jul 23, 2025

1 Min Read

laser cutting acrylic is one of the latest developments in our technology, making the manufacturing process of acrylic sheets more efficient and providing unparalleled precision when engraving, engraving or shaping. this high-performance technology opens up a world of creative possibilities.

Dec 19, 2024

1 Min Read

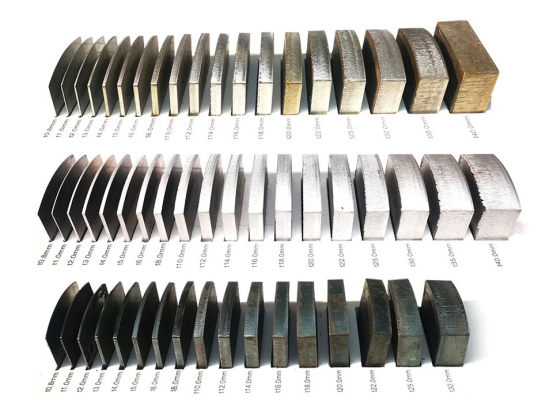

in the early days of automated metal processing, business owners often tended to purchase a entry-level cnc plasma cutting table or waterjet cutter for rough cuts of thick metal, and a fine cnc plasma cutter for precise cuts of thin metal. with the demand for manufacturing safety and environmental protection in metal processing, yag and co2 laser cutting machines laser cutting machines

Dec 19, 2024

1 Min Read

laser rust removal is a modern laser cleaning machine that effectively removes rust and corrosion from metal surfaces using a high-intensity laser beam. it provides a very accurate and environmentally friendly solution compared to other methods. the price of a rust removal laser depends on its functionality and power, ranging from approximately $10,000 for entry-level systems to over $100,000 for high-power systems.

Dec 19, 2024

1 Min Read

in the welding industry, laser welding is considered a powerful and complex joining process. it utilizes a highly concentrated beam of light known as a laser. on the target surface of the material, the laser beam generates intense heat at the point of contact and causes the material to melt and form a strong bond as it cools and solidifies.

Dec 19, 2024

1 Min Read

plasma cutters are versatile tools that can be used in a variety of industries to cut metal quickly and accurately. the cost of a plasma cutter can vary greatly depending on a variety of factors including brand, quality, power output, additional features, and intended use.

Jul 23, 2025

1 Min Read

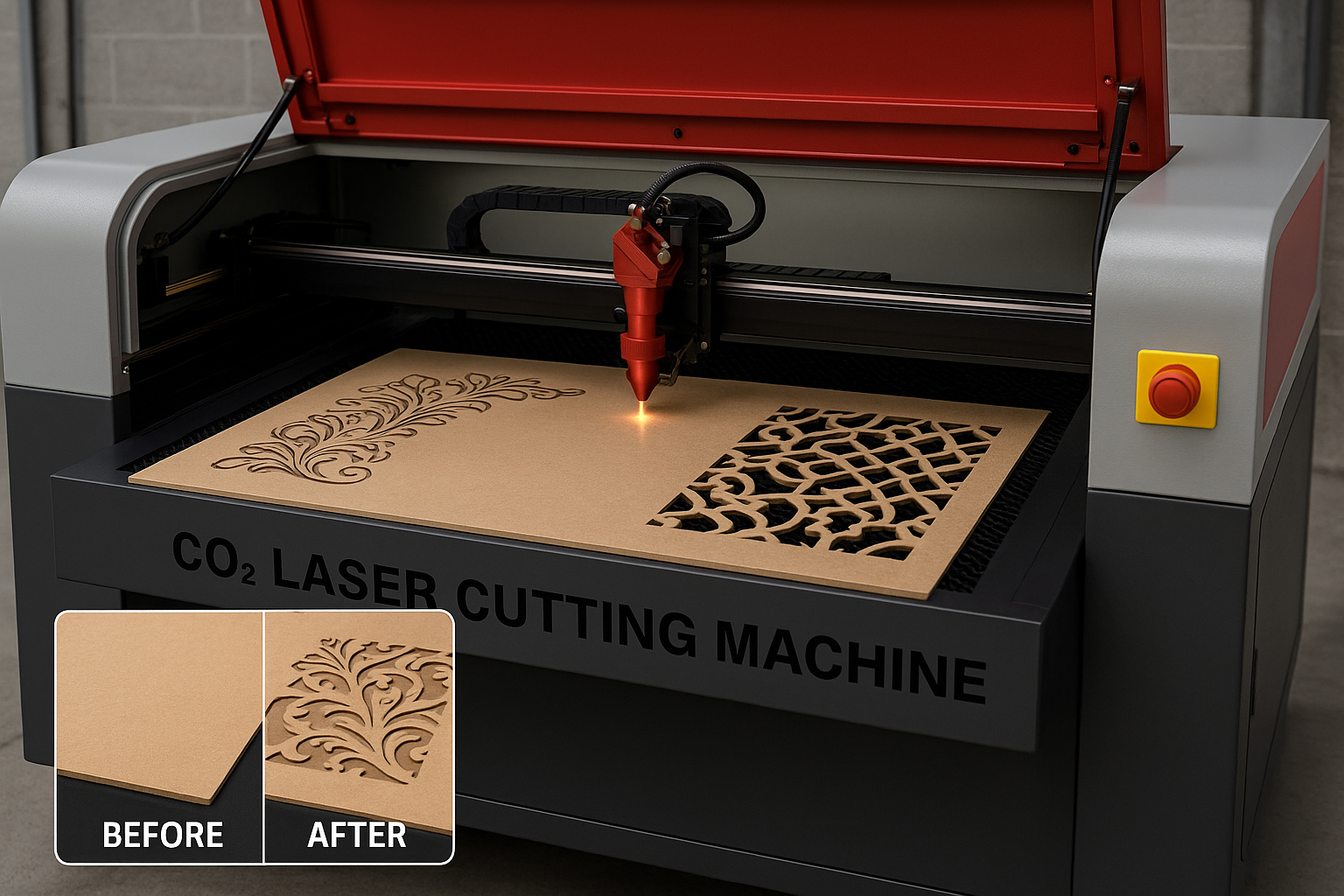

As industrial automation and intelligent manufacturing continue to advance, laser processing technology has become increasingly mature. In the field of non-metal materials, the CO₂ laser cutting machine stands out as an essential and advanced tool thanks to its high efficiency, stability, and excellent cutting quality. This article provides a comprehensive analysis of CO₂ laser cutting machines from four perspectives: working principle, application fields, technical advantages, and market prospe