In-depth Analysis of the Application and Technical Advantages of CO₂ Laser Cutting Machines in the Non-metal Processing Industry

In-depth analysis of carbon dioxide laser cutting machine

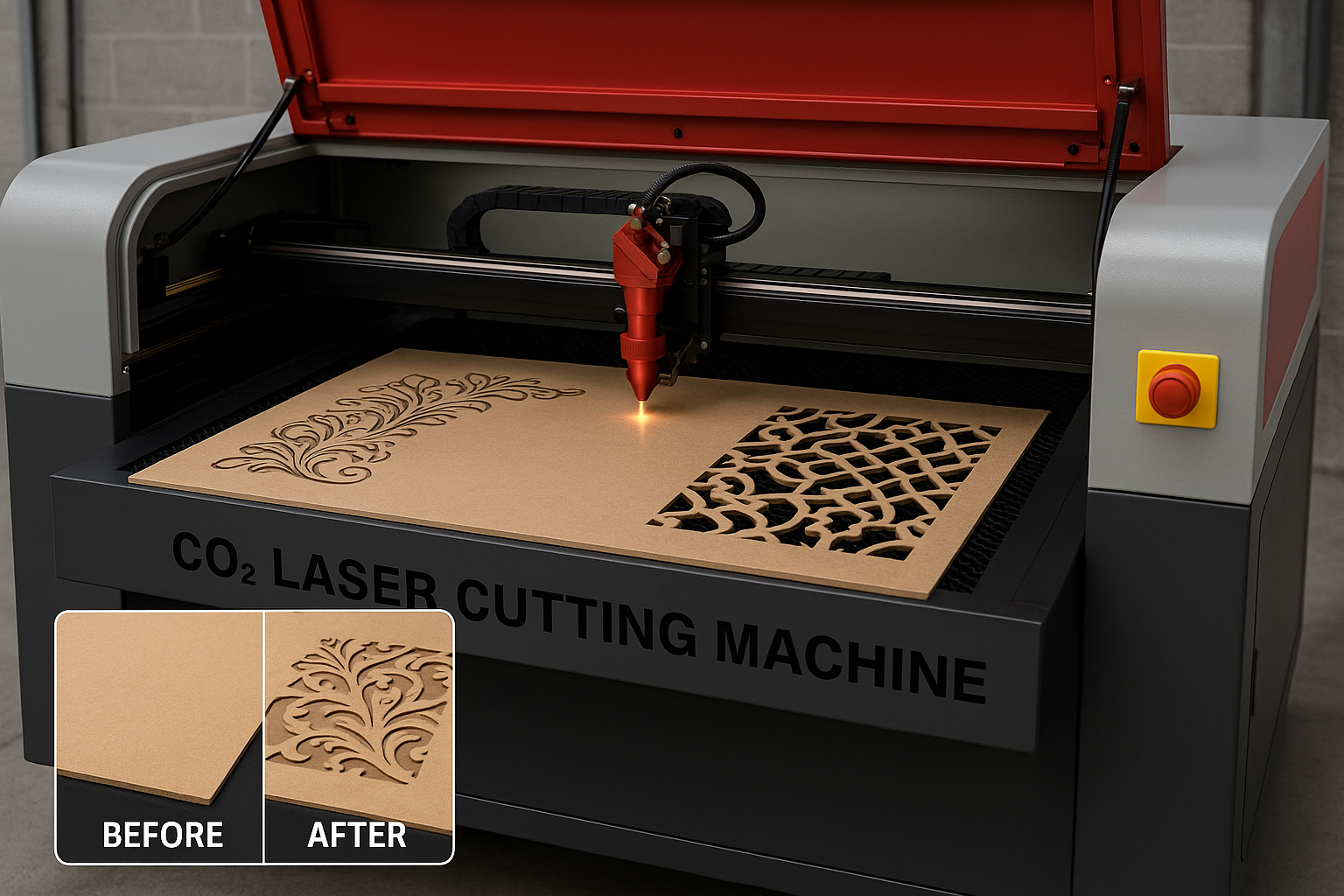

As industrial automation and intelligent manufacturing continue to advance, laser processing technology has become increasingly mature. In the field of non-metal materials, the CO₂ laser cutting machine stands out as an essential and advanced tool thanks to its high efficiency, stability, and excellent cutting quality. This article provides a comprehensive analysis of CO₂ laser cutting machines from four perspectives: working principle, application fields, technical advantages, and market prospects.

1. Working Principle: High-energy Infrared Beam for Non-contact Precision Cutting

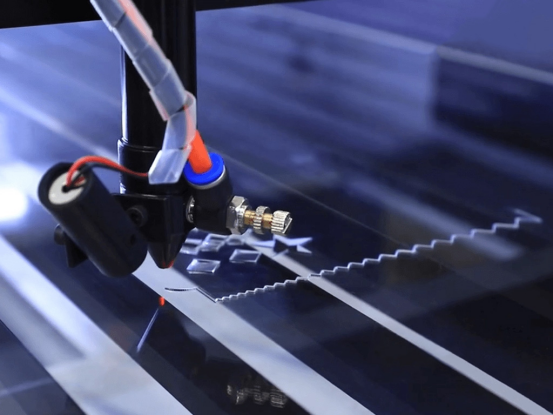

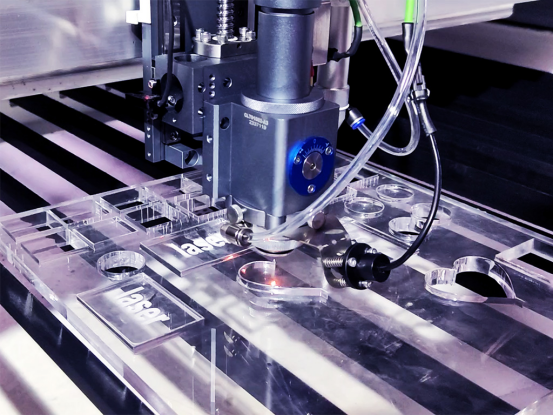

The CO₂ laser cutting machine uses a continuous wave infrared laser with a wavelength of 10.6μm, generated by exciting carbon dioxide gas. The laser is focused onto the material surface, where it rapidly heats and melts or vaporizes the material to achieve cutting. Since the process is non-contact, no physical force is applied to the material, effectively avoiding deformation or cracking and significantly improving cutting quality.

2. Applicable Materials: A Versatile "Blade" for Non-metal Industries

CO₂ laser cutting machines are widely used for a variety of non-metal materials, including but not limited to:

Wood (MDF, plywood, solid wood)

Acrylic (PMMA), plexiglass, PVC sheets

Plastics (PET, PP, PE)

Leather & Fabric (genuine leather, synthetic leather, Oxford cloth, denim)

Paper products (cardboard, honeycomb board)

Foam board, rubber sheets, KT board, films, and other soft materials

Traditional methods struggle to produce smooth edges on these materials, whereas CO₂ laser technology delivers clean, burr-free cuts with no need for secondary processing.

3. Industry Applications: Widely Used Across Multiple Sectors

Today, CO₂ laser cutting machines play a vital role in the following industries:

Advertising: Cutting acrylic letters, lightboxes, illuminated signs

Packaging: Precision cutting of cartons, shaped paper boards, blister molds

Apparel & Leather: Large-format fabric layout, pattern cutting

Architectural Modeling: High-precision cutting of wood, PVC, etc.

Crafts & Gifts: Customized patterns, intricate engravings

Electronics: Cutting of membrane switches, insulation materials

Automotive Interior & Furniture: Shaping of leather and textile coverings

4. Technical Advantages: Stability, Efficiency, Intelligence, Safety

✅ High-precision cutting

Equipped with a high-quality optical system and precision motion platform, the minimum cutting width can reach 0.1mm, with an accuracy tolerance within ±0.05mm.

✅ Intelligent control system

Powered by professional software that supports various file formats (DXF, PLT), compatible with mainstream design programs like CorelDRAW and AutoCAD. It also offers auto-nesting and optimized path planning.

✅ Automation-ready

Optional CCD vision positioning, automatic loading platforms, and zoned dust extraction systems make large-scale continuous processing possible.

✅ Eco-friendly and energy-efficient

Laser cutting produces no dust or fumes and operates with low noise. Equipped with purification systems, it ensures a clean workshop environment and complies with CE standards.

✅ Low maintenance costs

With a stable optical core and reliable performance, the equipment is ideal for 24/7 industrial production with minimal downtime.

5. Our CO₂ Laser Cutting Machines: Unique Product Advantages

As a professional manufacturer in the laser equipment industry, we provide CO₂ laser cutting machines with the following key advantages:

Fully customizable models: Multiple formats available (e.g., 600×400mm, 1300×900mm, 1600×1000mm) with laser power options from 80W to 300W.

Stable control system: Independently developed control boards for faster response and broader compatibility.

Durable structure: Industrial-grade steel frame ensures machine stability during high-speed operations.

Global service: Remote technical support for international customers; export-ready with global delivery.

6. Market Outlook and Development Trends

As application scenarios continue to expand, the demand for CO₂ laser cutting machines is steadily increasing, particularly in markets requiring personalized customization and flexible manufacturing. Future trends will focus on enhanced automation, intelligence, and environmental sustainability.

Conclusion

CO₂ laser cutting machines are not only essential for improving quality and efficiency in manufacturing but also a key enabler of Industry 4.0. We remain committed to ongoing R&D investment and technological innovation to provide our clients with smarter, more efficient, and more reliable laser processing solutions.

📞 WhatsApp: +86 18958697435

📩 Email: eastlaserok@gmail.com

🌍 Official Website: www.east-laser.com